Increased cutting efficiency from Work in Process (WIP)machining.Support for canned and long code output.

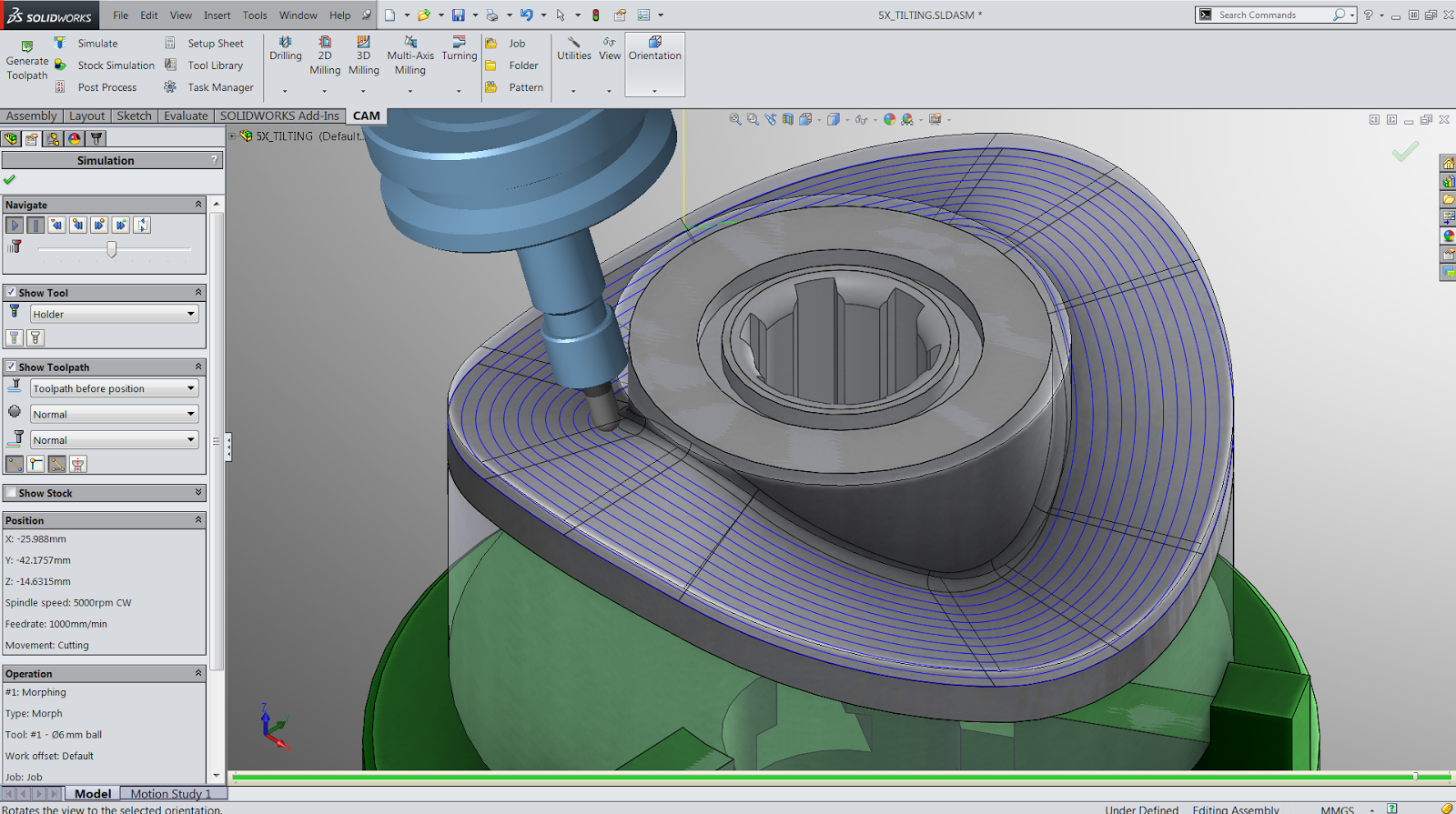

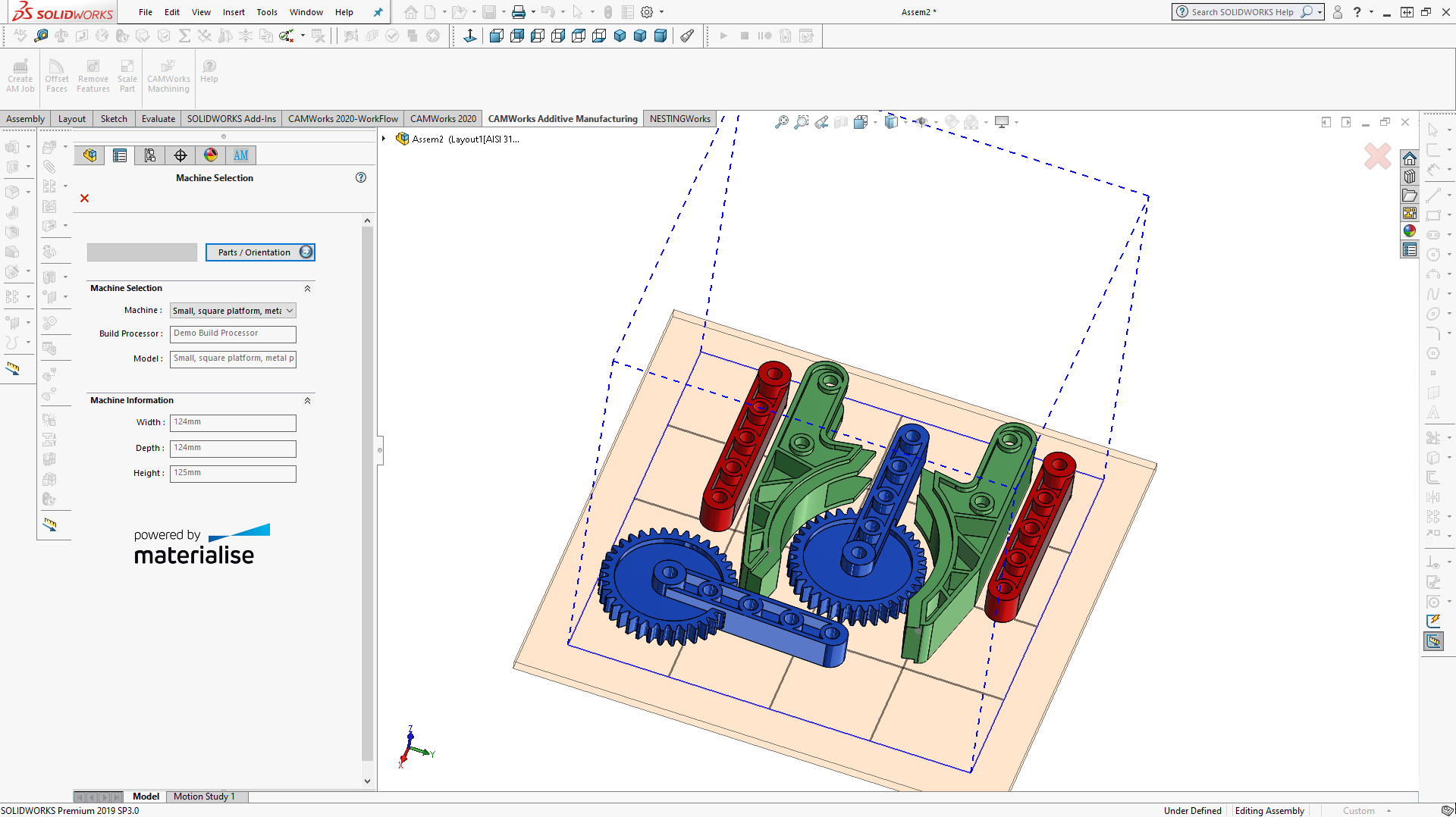

Support for sub-spindles and twin turrets.Incorporates error free and gouge protected tool paths.Adaptive roughing can reduce machining time up to 40% over conventional roughing with less wear.Multi-tasking for improved speed and efficiency.Simple and complex parts can be cut quickly and accurately with a high quality toolpath.The 3 Axis cycles have been developed for speed, accuracy and efficient memory usage.Includes 2.5 Axis capabilities plus routines to machine complex, contoured surfaces outinely encountered in mold making and aerospace applications. Includes automatic roughing, contouring (finishing), thread milling and single point (drilling, boring, reaming, tapping) 3 Axis Milling It does not store any personal data.CAMWorks is an intuitive, feature-based CAM solution that helps manufacturers increase productivity and profitability through best-in-class technologies and adaptable automation tools that maximize machining efficiency. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. The cookie is used to store the user consent for the cookies in the category "Performance". This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. The cookies is used to store the user consent for the cookies in the category "Necessary". The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". The cookie is used to store the user consent for the cookies in the category "Analytics". These cookies ensure basic functionalities and security features of the website, anonymously. Necessary cookies are absolutely essential for the website to function properly.

0 kommentar(er)

0 kommentar(er)